Rooftop Care and Protection for Commercial Solar PV Systems

A commercial roof is a valuable asset that can be vulnerable to damage if proactive planning and careful practices are not used. This is why rooftop protection is an integral part of SunPeak's project execution strategy. Here we highlight a few of the key measures we take to protect customer property when installing solar on a commercial rooftop.

The Importance of Site Assessments

In the very initial phases of project planning, SunPeak team members come onsite to fully evaluate the proposed project space and ensure the project can be designed with the highest quality standards and installed with utmost care for the customer’s property. During this site assessment, our goals include:

• Document the building's current electrical infrastructure and project space. This includes using GPS survey technology to conduct a thorough survey of the rooftop, mapping the location of HVAC, installed equipment, drains, and other physical characteristics within or near the installation area.

• Evaluate the existing rooftop structure and materials, engaging the customer's roofing contractor or a third-party roofing consultant if concerns arise or potential defects are detected.

• Note any considerations for project safety and construction preparations.

Rooftop Structural Protection

Akin to other roof-mounted equipment, a solar PV system adds load to the building, making it very important to assess the strength and weight-bearing capacity of the roof in the earliest stages of design. SunPeak verifies the existing structure will not be compromised by solar in several ways:

• Ballast Planning. Most of SunPeak’s flat-roof installations use a ballasted (penetration-free) mounting design. A ballast plan is created to document the placement of weight to be used to secure the system to the roof. This plan is carefully designed with a margin of safety for regional seismic, wind and snow-loading codes, as well as consideration for the customer’s existing rooftop equipment, the condition of the roof substrate, and other metrics from the previously-conducted structural assessment. The ballast plan is reviewed by a third-party Professional Structural Engineer to ensure independent approval.

• Equipment and Material Planning. All equipment to be used on the roof during the installation process is incorporated into a material staging plan. This plan, which is also reviewed and approved by the Professional Structural Engineer, outlines how equipment and materials will be transported to the roof and where they can be safely stationed once loaded on the roof.

Some of our equipment considerations include:

• Crane Loading. A crane is used to lift all materials to the roof, which we do in small quantities to prevent excess loading. The ability to reach farther onto the roof also keeps workers away from the roof edge and OSHA compliant.

• Cart Transport. After a material load reaches the landing area on the roof, materials are placed on

rubber-tired carts and pulled in small loads to the work or temporary staging areas. This ensures the roof structure is not compromised by leaving a heavy load in one spot for an extended period.

Above: SunPeak installers use a cart to transport solar panels safely across a large commercial roof at a customer site in Central California.

Rooftop Surface Protection Measures

Of equal importance to structural protection is the consideration for the roof’s membrane, which acts as a strong, watertight barrier. SunPeak uses an abundance of care to safeguard the existing roof membrane:

• Penetration-Free Mounting. With no screws or sharp hardware, accidental membrane penetration is very unlikely.

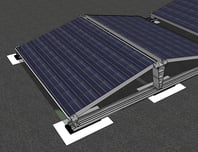

• Pre-Assembled Racking. Using racking that is assembled largely at the factory, the chance of loose pieces or tools unintentionally penetrating the roof surface is greatly limited.

• Padded Racking and Slip Sheets. The under surface of SunPeak’s aluminum racking (mounting structure) features a built-in rubber pad to eliminate contact with any sharp or hard edges. Additionally, SunPeak uses slip sheets, which are small sections of membrane-like roofing material, as an added layer of protection between the racking's padded surface and the roof's membrane.

• Special Care for Ballasted Roofs. When a customer has a ballast (rock) roof system in place, SunPeak carefully removes the ballast stone from landing zones, cart paths, and array locations using surface-safe tools.

"A rooftop PV system should have no negative impacts on a building if installed correctly. Building owners’ key concerns about PV systems typically include the potential impact PV may have on roof integrity, roof warranties, building permitting, and business operations, however, all of these risks can be mitigated or eliminated with a quality solar provider.”

—U.S. Department of Energy, Office of Energy Efficiency and Renewable Energy

Roof and Facility Protection: A Holistic Approach

Investing in solar should always enhance your overall business operations. SunPeak’s holistic approach provides additional considerations that can affect the overall facility:

• Jobsite Safety. Safety is a core value at SunPeak. Our first priority onsite is always the safety of those within or near the work zone, including our crew, our customer’s employees, and the public. Our construction team is highly trained, follows established safety plans, and takes every precaution to ensure a safe, successful solar installation.

• Preservation of the Existing Roof Warranty. SunPeak proactively works with the Roofing Contractor of Record to ensure our actions and work fully comply with the customer’s existing roof warranty.

• Roof Health and Maintenance. If SunPeak identifies any existing or potential roof issues during our site assessment, we address them with the customer.

• Protecting Established Insurance Coverage. Because of SunPeak’s rigorous quality and safety initiatives, our systems have been approved for coverage by some of the largest business and property insurers in the country. SunPeak’s use of tier-one components and our QA/QC processes including independent wind tunnel and safety testing, ensure our customers maintain their current premiums and also have peace of mind regarding their facility.

"Being entrusted with customer property is something we take very seriously at SunPeak. It’s an honor and an opportunity that we never take for granted. By going above and beyond for our customers from the very beginning, we demonstrate the caliber of our commitment for decades to come.”

—Tyler Potter, PMP, SunPeak Project Manager

Key Takeaways

SunPeak's standard of care concerning rooftop protection employs a spectrum of proactive measures including early information gathering, structural analysis, comprehensive regard for the physical surface of the roof, and other measures to protect each customer's overall facility.

If you have questions about our commercial rooftop protection measures or you are interested in investigating solar PV for your facility, please contact us.