What factors affect solar panel longevity? Are there ways for solar customers to prolong the life of their solar PV system? Read this blog from SunPeak’s experts to discover the answers to these questions and more.

Accounting for solar panel degradation

When businesses make an investment in new equipment, they should have a realistic idea of the asset’s expected useful life and its anticipated performance year over year. After all, these key metrics help calculate the asset’s payback period and the overall return on investment (ROI) for the organization.

An investment in solar is no different. Solar panels are widely regarded as a very durable and long-lasting application, but like any technology, their productivity naturally decreases over time.

This process is called panel degradation, and solar providers must incorporate a predictive model for degradation to provide prospective system owners with the most accurate ROI projections for their project.

Below, we have provided useful information to commercial solar system owners about solar panel longevity, how degradation rates are calculated and applied and how the selection of the right solar provider can further maximize the long-term productivity and profitability of every system.

Panel degradation: What to expect and when

Under normal conditions, solar panel degradation is a gradual process.

The National Renewable Energy Laboratory (NREL) – a federal agency dedicated to the research, development, commercialization, and deployment of renewable energy technologies – has conducted longitudinal studies for more than 40 years on the topic of panel degradation.

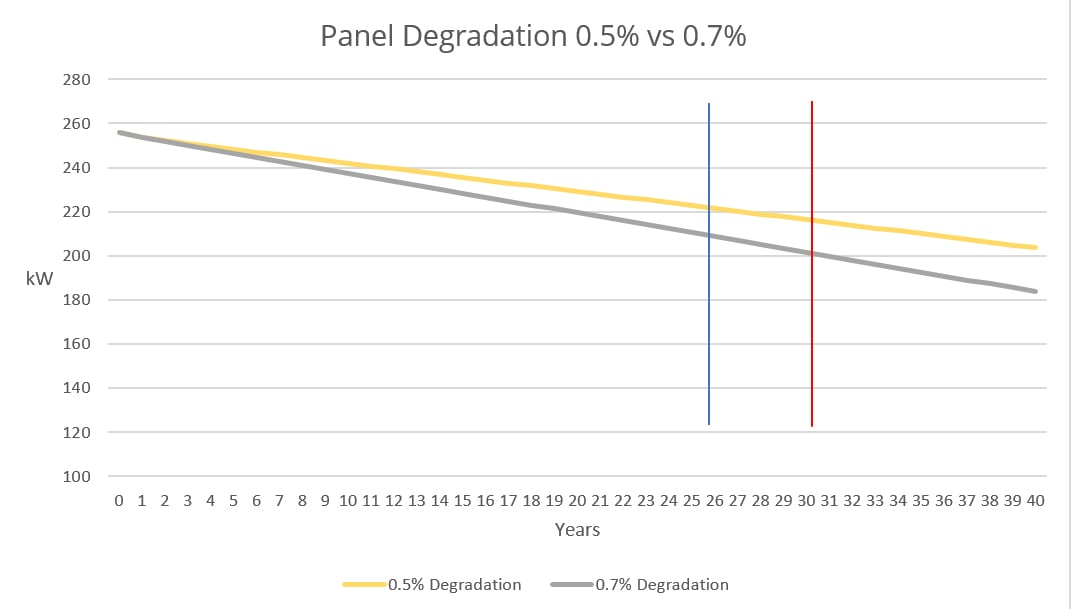

After studying thousands of solar installations with different panel types, installation styles and weather and climate conditions, NREL’s most recently published data indicates that panels typically experience a median reduction in power output of 0.5% – 0.7% per year with up to a 1% degradation in the first year.

This means solar panels that are installed properly should still retain at least 80 – 85% of their full output capability at 25 years of operation.

If utilizing high-quality components sourced from established manufacturers, commercial solar system owners should expect to see these statistics supported within the product’s performance warranty.

Figure 1: Industry standard degradation rates are shown, including 1% in the first year and .5% and .7% rates. The blue line represents warranty coverage, and the red line represents a system’s typical 30-year investment lifespan. As seen above, panels do not fully degrade by this 30-year mark; many can continue to produce electricity for an extended time period, though at a lower level.

How do weather and climate conditions affect solar panel degradation?

NREL’s studies on solar panel longevity and degradation, perhaps unsurprisingly, revealed that sustained climate extremes (especially perpetual heavy winds and desert climates with intense UV radiation) are associated with higher degradation rates.

Conversely, panels installed in more moderate climates – even northern and midwestern regions of the United States that experience significant snowfall – are associated with the lowest rates of degradation.

Apart from truly catastrophic weather events, quality panels that are installed properly are quite resilient to intermittent weather conditions. NREL highlighted this in May 2017 when a significant hailstorm pelted the organization’s Golden, Colorado headquarters.

NREL closely documented the storm’s impact on the performance of its own solar installation, noting that only one of the system’s 3,168 panels was damaged. The system’s performance monitoring system was able to confirm that the power efficiency of the remaining 3,167 panels was unchanged by the storm.

How can solar developers help protect customers from undue degradation?

Knowing that panel degradation influences electrical production over time, experienced project developers like SunPeak take important measures to safeguard their customer’s investment.

As a first step, historical weather patterns and environmental conditions for the site will be considered as part of the project assessment and feasibility process.

Secondly, a panel degradation model will be incorporated within the initial proposal process, so that all the system’s production and financial projections reflect expected panel efficiency changes over time.

SunPeak implements additional safeguards to prevent other possible causes of degradation. Some examples include:

1. The prevention of microfractures

Tiny cracks can form on the panel’s surface or within the silicon found inside the panel and can result in reduced panel efficiency over time. Therefore, minimizing physical stress to panels during the transportation, delivery and installation processes is very important.

Comprehensive plans documenting how panels will be stored and moved throughout the jobsite, as well as proper training for site teams help ensure that panels will not be damaged during installation.

SunPeak applies extensive Quality Assurance and Control measures that include both visual inspection as well as panel performance testing at established points in the manufacturing process, upon delivery, and before system commissioning.

Furthermore, SunPeak uses highly specialized tools in order to standardize the torque (force) applied to each screw in the panel’s racking. This ensures that panels are properly secured to withstand wind without damaging their surface.

Torque and other installation data are recorded and included in the system’s turnover documentation, which also supports the panel’s warranty.

2. The use of high-quality panels

Utilizing high-quality solar panels produced by reputable manufacturers with proven product performance is also critical to solar panel longevity. Not only will the manufacturer be focused on vigilant production, transportation, and documentation processes, they stand behind their products with solid warranties.

SunPeak systems utilize Tier 1 solar panels, sourced exclusively and directly from internationally leading solar panel manufacturers, and our team regularly visits our manufacturing partners' facilities as part of our Quality Assurance and Quality Control processes.

In addition to long-term, comprehensive product warranties from our manufacturers, SunPeak also provides customers with its own workmanship warranty.

3. Pre-construction site assessment

A proper site assessment performed by a skilled solar provider can mitigate many potential issues before they surface.

Solar technicians will look for any nearby elements that could potentially impair the system. Trees, power lines, roof equipment and other factors will be considered and reflected in the project’s final design.

4. Ongoing performance monitoring.

The best way to be sure that a solar PV system is working properly is to monitor its performance continuously. With SunPeak’s Operations & Maintenance (O&M) plan, customers have access to a state-of-the-art, cloud-based monitoring platform that provides real-time performance data and error detection for their system.

If an issue arises, SunPeak technicians are alerted and can troubleshoot or remedy the problem, and coordinate warranty claims on behalf of the customer, if needed.

Key takeaways

With no moving parts, solar PV systems are remarkably reliable and provide businesses with a long-term, durable and useful asset.

While a moderate amount of solar panel degradation is normal and expected, systems that are well designed, properly constructed and professionally monitored are more than likely to last their lifetime and beyond.

Unlock the long-lasting power of solar with SunPeak

See how solar can help your business realize cost savings and sustainability benefits. Request your no-cost, no-obligation Solar Feasibility & Financial Analysis with SunPeak today.