Solar PV systems are designed to function with minimal involvement once the equipment has been commissioned, however, it is crucial to have a way to monitor PV systems to ensure they are operating at full capacity.

One system owner might choose to take an active approach, verifying the equipment is running each day by looking at the inverter LEDs. Another might review utility bills as a way of passively monitoring the generation of their PV system. A more efficient and rigorous method is to utilize supervisory control and data acquisition (SCADA) systems as a means of verifying a system’s operation. This is accomplished by connecting all components together with communication cables so that a data logging device can collect data points from each component (inverters, energy meters, weather sensors, etc). The raw information is transmitted in real-time to a web-based platform that manipulates and presents the data in a meaningful way.

This platform serves as the eyes and ears of solar Operations & Maintenance (O&M) technicians, allowing them to efficiently direct troubleshooting efforts and maintenance operations. Leveraging this digital toolbox for better system performance requires personnel who are familiar with networking/IT principles, controls engineering, the electrical trade, data acquisition systems, and all aspects of solar PV. Sound O&M service will protect the owner’s asset and boost their return on investment by maximizing long-term production and minimizing downtime for repairs.

Some techniques for conducting solar operations, maintenance, and monitoring are listed below. Many of these rely on the information contained in the web platform to analyze system performance and provide effectual support.

-

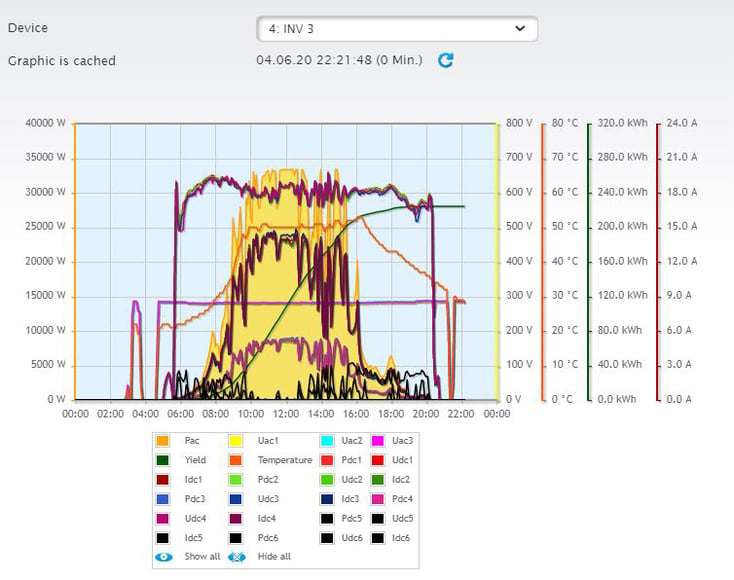

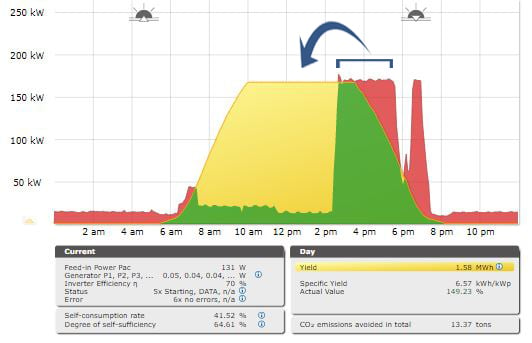

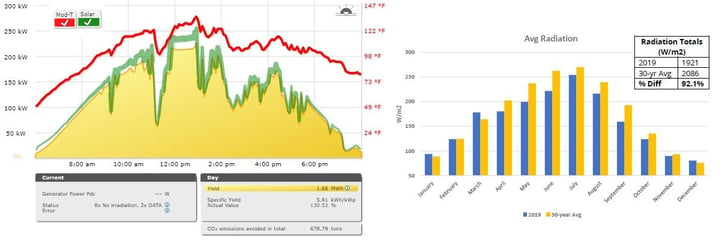

Advanced user interface with highly granular graphical analysis tools quickly isolate strings or inverters that behave abnormally:

-

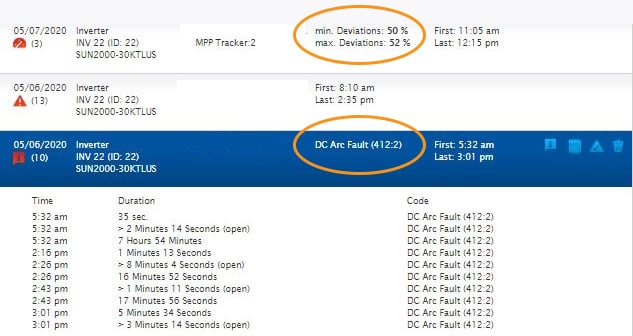

Setting deviation thresholds between like components for advanced detection of under-performance, shading/soiling concerns, and component degradation:

-

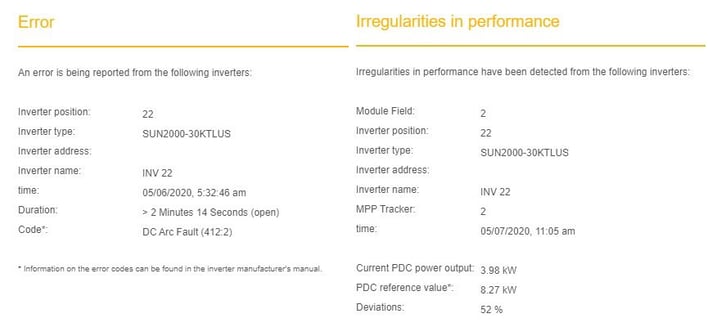

Specific error codes registered by inverters are used to diagnose the type of problem and prepare for truck rolls (onsite technician support).

-

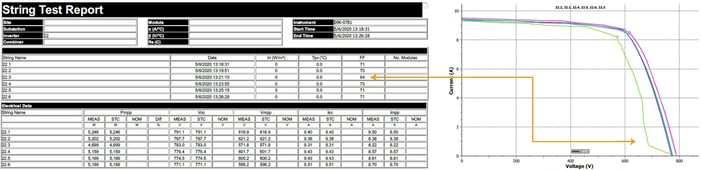

Using PV test equipment to conduct field troubleshooting and repair of malfunctioning components:

-

Automatic notifications can be sent to alert users of system errors, performance deviations, and network connection problems as soon as they are detected:

-

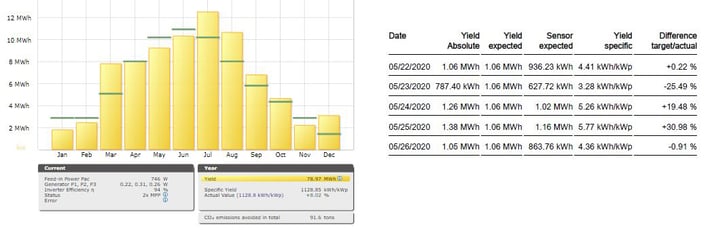

Custom reports can be configured to collect yield information and compare production forecasts to actual production data:

-

Combining data from other DAS (Data Acquisition System) components can help to identify ways of changing operations to maximize the benefit from a PV system.

-

Shifting afternoon factory production to peak solar window to reduced demand charges from the utility.

-

Comparison of yield data against weather station measurements to normalize weather fluctuations:

As you can see, modern solar PV monitoring is a robust, efficient and helpful tool that assures customers their solar system is working reliably. It also provides O&M personnel with an effective means to detect potential maintenance needs and remedy problems in real time. At SunPeak, remote monitoring is an essential element of our O&M program and long-term commitment to our customers.

All images courtesy of SunPeak and Solar Data Systems, Inc.