Applying new technology and tools can streamline work and even provide greater accuracy and detail. A great example is the expanding use of drones as a tool for solar project development and performance monitoring. SunPeak's adoption of this technology for select applications creates greater efficiencies for our customers and team. Read on to learn more.

Drones: New innovation expands options across industry

Unmanned Aerial Vehicle (UAV) – or “drone” – technology is evolving quickly and broadening the possibilities for all sorts of industries and applications from food and parcel deliveries to wildlife conservation.

Until recently, drone use within the solar industry was somewhat limited aside from tracking project progress, documenting completed projects, or creating marketing content.

Now, new advancements in drone accessories and software add value to the entire solar project life cycle, from the initial survey of a prospective site to performance testing and maintenance inspections.

Here are three ways drone technology is contributing to the advancement of solar:

1. Drone-assisted site surveying

A critical step in designing a solar array is to map out a potential installation site to locate obstructions and identify shading concerns.

Methods to obtain site measurements on the ground or on a rooftop have advanced rapidly. What started with measuring wheels, tape measures, and hand-drawn notes quickly evolved to handheld GPS survey tools, greatly improving the accuracy of measurements and allowing a single person to collect the data in digital format. While this represents a large process improvement, handheld GPS surveys still require each data point to be collected at location with potential for human error.

Using drones as solar site survey tools are the next step in this evolution; with recent advancements in the resolution of Lidar (light detection and ranging) payloads, measurements accurate to less than an inch can be obtained while the drone surveys a potential project site in just minutes.

Not only is the time requirement vastly reduced, but the technician never has to set foot on rooftops or grounds that may present a safety hazard if under construction.

A screenshot of information gathered by a drone, including a birds-eye view of a planned area for solar panel installation and site measurements. Image courtesy of Sitemark and Hammer.

A drone can be pre-programmed with a flight pattern and local reference points, allowing the technician to perform other aspects of the site assessment while the drone is capturing the survey data.

Using post-processing software, the drone data is cross-referenced against known lat-long points to produce a 3-dimensional map of the site.

This data can be automatically imported into CAD software to determine the optimal layout for solar panels to maximize energy production and minimize the impact of shading.

These benefits represent an order of magnitude increase in the efficiency and safety of site surveys.

2. Drone-assisted solar project commissioning

When the time comes to commission a solar PV system, it is critical that baseline data is collected to evaluate the performance of the solar panels, inverters, and electrical equipment.

This is important to ensure each component is performing at or above the manufacturer’s warranted specifications at the time of commissioning.

The conventional way to obtain this data is through I-V curve tracing, an electrical test that compares the actual power output of a string of modules with its expected output, normalized for environmental conditions.

This method of testing must be performed manually on each string of modules and requires time investment for a skilled technician to operate expensive equipment.

I-V curve tracing also faces the problem of low-resolution data. Any strings that indicate lower performance must be segmented to run further tests that isolate individual faulty modules.

Moreover, with the adoption of the Rapid Shutdown requirement in the 2017 National Electric Code, I-V curve tracing does not work with the Module Level Power Electronics (MLPEs) that are required to fulfill Rapid Shutdown.

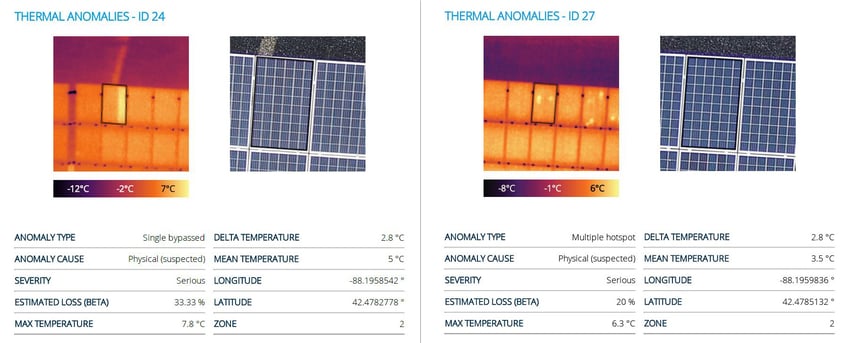

Fortunately, modern drones can be outfitted to do performance testing in a fraction of the time on any system. By carrying a thermal infrared (IR) camera payload, drones fly over a PV site and measure the infrared heat signatures of the solar modules.

This data is entered into software tools and overlaid with visual RGB images to display a high-resolution heat map of the site.

When the drone-based heat map is used with a traditional PV monitoring platform, the system’s performance can be evaluated against commissioning requirements.

Individual performance anomalies can be automatically diagnosed based on the heat signature of common failure modes in solar modules.

Drone-based heat maps, courtesy of Sitemark and Hammer.

3. Drone-assisted solar Operations & Maintenance (O&M)

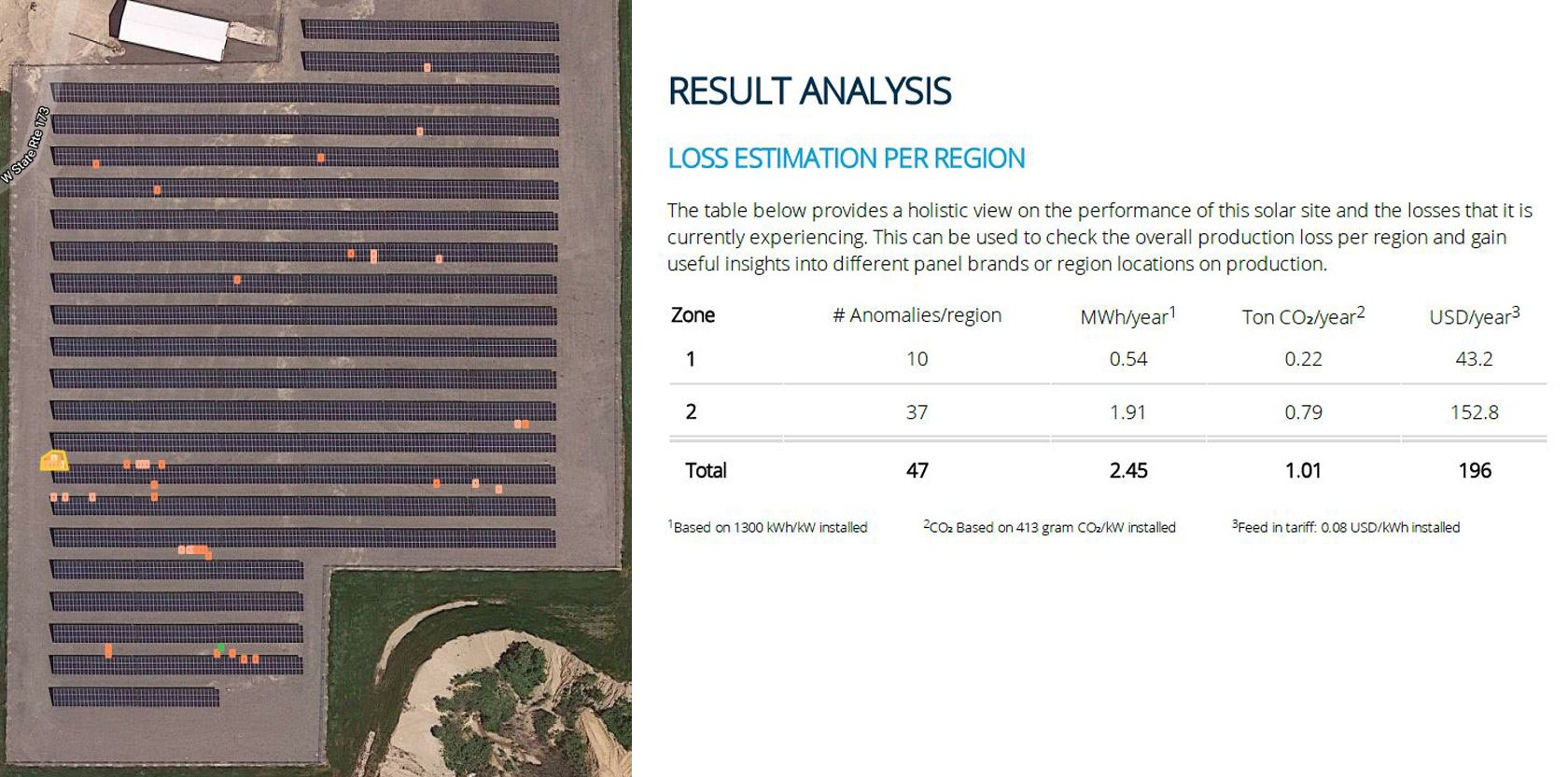

As a PV system ages, the baseline data from commissioning provides a reference point to determine the degradation rate of solar modules at a given site. If it is determined that modules are underperforming, drone data can be used to file performance warranty claims.

Traditional monitoring techniques limit the scope of failure detection to string-level resolution. Drone IR analysis can pinpoint individual bypass diode failures within any module in a string.

This increases the granularity of failure detection by a factor of 60 in a typical string. This level of analysis would otherwise be invisible to system owners and operators, causing losses in revenue from undiagnosed issues.

A screenshot of information gathered by a drone, including a birds-eye view of a planned area for solar panel installation operations and maintenance results analysis data. Image courtesy of Sitemark and Hammer.

There are several other O&M applications where drones can be used to improve efficiency. Drones can be used to:

- inspect a PV site after a severe weather event to quickly assess damage to modules and equipment

- identify soiling patterns that cause hotspots and reduce performance of entire strings of panels

- develop a cadence for optimal cleaning frequency of solar modules

Using drones for O&M can help technicians strategize reactive maintenance truck rolls and protect the owner’s asset. The utility of drone technology for solar O&M represents massive gains in cost savings for clients and O&M providers alike.

Future drone applications for the solar industry

In a growing industry like solar PV, new products and technologies are introduced onto the market frequently.

SunPeak’s internal R&D team regularly investigates and tests promising technologies, including drones as solar site survey tools, making implementation choices as products prove to be both reliable and cost-effective for our project processes.

We are excited to see how quickly drone technology has improved in a relatively short amount of time, and it is an area that SunPeak will continue to track closely.

We expect and look forward to wider implementation of the technology as even more powerful and capable drones become available.

Ready to empower your business with solar?

If you’d like to take advantage of solar for your organization, SunPeak’s skilled team will provide a customized no-cost, no-obligation Solar Feasibility & Financial Analysis for your site.