Evaluating the Structural Integrity of a Building In Preparation for Rooftop Solar

To begin, very few potential projects fail due to structural reasons. Most buildings are engineered with a high enough factor of safety to permit the added collateral load that the rooftop solar system will add to the roof. In the many hundreds of projects SunPeak has constructed or evaluated over the years, only a few encountered structural limitations by the building.

Most flush-mounted solar systems will be below 3 psf (lb/ft2). These would be systems typically installed on a pitched roof and attached either via a non-penetrating standing seam clamp (e.g. S-5! clamp) or through direct roof penetration. Due to this, roof loading is minimal because the only elements adding weight are the solar modules (panels) themselves, and the aluminum racking.

For low-slope (flat) roofs, SunPeak typically installs a ballasted racking system that uses an array of ballast (typically 15 lb. concrete blocks) to hold the system to the roof via gravity alone. This approach is also non-penetrating but does add some additional load due to the added weight of the ballast. With these systems, solar roof loading will have more variance but is commonly below 5 psf.

Primary Factors Affecting Roof Loading for a Commercial Solar Installation

A number of considerations are evaluated when determining structural fitness for solar.

1. Wind zone. The windier the region, the higher the ballast that is necessary to prevent both lift and lateral movement.

2. Terrain considerations. Urban and suburban areas generally benefit from wind breaks from other buildings vs. rural projects without nearby wind obstructions.

3. Racking / mounting design. East/west (dual-tilt) ballasted designs will require less ballast than traditional south-facing systems, as they are more aerodynamic and contiguous.

4. Attachment means. SunPeak’s standard low-slope (flat roof) solution is a non-penetrating ballasted approach, whereby the system is held to the roof surface by gravity alone. There are options that can supplement this approach, if required, to lower rooftop loading such as:

a. Adhered solutions, whereby the system is adhered to the roof with structural adhesive, and/or

b. Roof penetration, whereby a positive attachment is made by securing to the underlying roof structure. Rarely are either of these alternative methods required or used, but they are available for unique projects (tall structures, such as high-rise multi-family dwellings, or areas with seismic potential, such as Northern California)

5. Height of building. Higher buildings require more ballast due to the greater wind load.

6. Solar array layout. The more contiguous the layout, the lower the loading. Within the solar array, perimeter ballast is higher than interior ballast, therefore larger arrays require less average ballast than smaller arrays as a function of [total weight/total area].

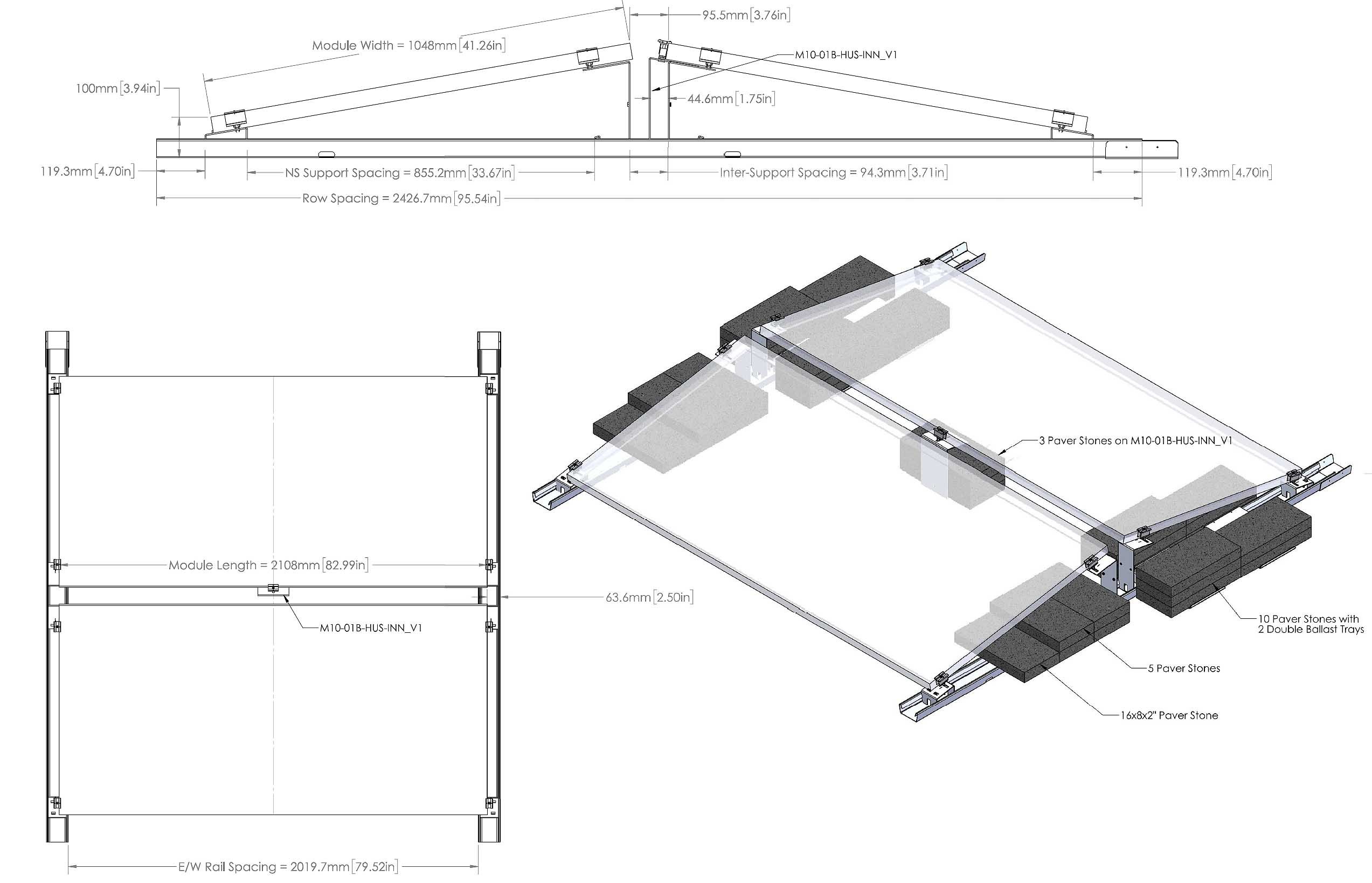

Above: The size, spacing, weight, and placement of all system components including the solar racking, solar modules (panels), inverters and ballast are considered and carefully planned within the structural engineering process.

Commercial Solar Structural Analysis: Example Metrics

For context, the below example provides metrics from an actual SunPeak commercial solar project in the Chicagoland area. Metrics were pulled from stamped structural reports that were used to support procurement of racking and the structural engineering process. Again, all of these values are project-specific, but this provides a common overview of what to expect:

Governing Standard |

ASCE 7 Chapter 6: Wind Loads (90 mph) Chapter 7: Snow Loads (Zone 7) |

| Project Location | Chicagoland (IL) |

| Building Height | 39 ft. |

| Terrain Formation / Category | Flat Plane / Category B |

| Racking Configuration / Design |

East / West (Dual-Tilt) |

| Solar Module Weight | 2.3 psf (lb/ft2) |

| Mounting/Racking Weight | 0.4 psf (lb/ft2) |

| Avg. Ballast Weight | 1.9 psf (lb/ft2) |

| Total Additional weight (sum of above components) | 4.6 psf (lb/ft2) |

It is important to note that the above 4.6 psf is an average load, whereby total added weight (solar panels + racking + ballast + roof protection membrane) is divided by the area of the solar system. Interior loads within the array will be lower than average and perimeter loads where ballast is biased to prevent edge lift/slip will be higher than average.

Key Steps for a Rooftop Solar System's Structural Analysis and Approval

SunPeak's standard process for engineering a ballasted solar system for a rooftop commercial project on an existing building would be:

1. Development of a conceptual layout. This would be driven by the desired system size and the rooftop obstructions or setback constraints.

2. Development of a ballast plan. Using the relevant inputs and the conceptual layout in step #1, the racking configuration is modeled using wind tunnel test results to establish both quantity and placement of required ballast for securing the system to the roof.

3. Structural assessment. The results of step #2 provide an information input to a structural engineering assessment of the proposed solar system in the context of the building’s structural design and ability to support additional collateral load.

4. Structural approval. All projects are stamped by a professional structural engineer prior to any procurement, permitting or construction.

Common Reasons a Building Cannot Structurally Support Rooftop Solar

On rare occasion, there can be an issue with a building not being able to hold the additional weight of a rooftop solar installation, which would be identified in step #3 above. Most commercial/industrial buildings are built with sufficient margins of safety to accommodate ~ 5 psf.

In our experience, when a building has structural limitations it’s generally due to either:

1. Inexpensive buildings (e.g. agricultural outbuildings) or special structures (e.g. gas station canopies) that were not designed for additional loading, or

2. Buildings that have already had a considerable amount of additional roof loading added through aftermarket installations of rooftop apparatus (e.g. HVAC, ventilation, laboratory needs, etc.).

Key Takeaways

In most cases, commercial and industrial buildings have adequate structural capacity to add rooftop solar. To know for sure, a thorough site assessment will be conducted, and then site considerations, local weather and building codes, and equipment selections will all be incorporated into the structural engineering process before a final system design would be approved for construction.

SunPeak can easily evaluate any project for feasibility - structural or otherwise. When rooftop solar is not viable, for example, quality alternatives such as ground-mounted solar or solar carports may be considered if land is available. SunPeak project developers have experience with many different types of solar applications and can provide a comprehensive overview of options to meet your organization's sustainability and cost-savings goals. Please contact us for further information or if you need help assessing the suitability of solar for your business or organization.